Guide to designing off-grid and hybrid solar systems

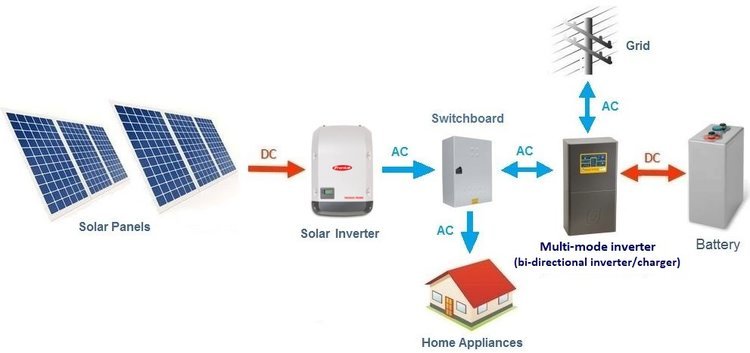

Diagram - Basic configuration of an AC coupled hybrid grid-connected power system

This is a technical guide for those with a basic understanding of solar and off-grid inverters. For less technical information, see the basic guide to selecting a home grid-tie or off-grid solar battery system. Solar and battery storage systems should always be installed by a licensed electrical professional.

Basic Steps to Designing An off-grid Solar System

Before purchasing any equipment required for a solar battery (hybrid) or off-grid power system, it is very important to understand the basics of designing and sizing energy storage systems. As explained below, the first part of the process is to use a load table or load calculator to estimate the amount of energy needed to be generated and stored daily. If you cannot develop a load table, a professional solar installer or system designer should be consulted.

Step 1 - Estimate the loads

The most important part of designing any off-grid solar or battery system is calculating how much energy is required per day in kWh. For grid-connected sites, detailed load data can often be obtained directly from your electricity retailer or by using meters to measure the loads directly. For off-grid or stand-alone power systems, always start by using an off-grid load calculator (load table) for summer and winter. The load table can also be used to estimate surge loads, power factors, and the maximum demand required to size an appropriate off-grid inverter.

Step 2 - Battery sizing

Battery capacity is measured in Ah (Amp-hours) or Wh (Watt-hours). Lead-acid (deep-cycle) batteries are sized in Ah, while lithium battery capacity is generally measured in kWh (kilowatt-hours). After using a load calculator to estimate the average daily loads in kWh, you need to determine the number of days of autonomy (continuous days without sunshine) you require the battery to last. Typically, two days is the minimum for lithium battery systems, while the less efficient lead-acid batteries are generally sized for three or more days.

Additionally, all loss factors must be considered to ensure the battery size is adequate to meet the loads, including inverter losses, temperature derating for lead-acid batteries, maximum allowable depth of discharge (DoD) and round-trip efficiency. Also, consider battery type and chemistry, battery voltage range, and maximum battery charge rate (C rating), as explained in Section 6 - Battery Selection and Sizing.

Step 3 - Solar array sizing

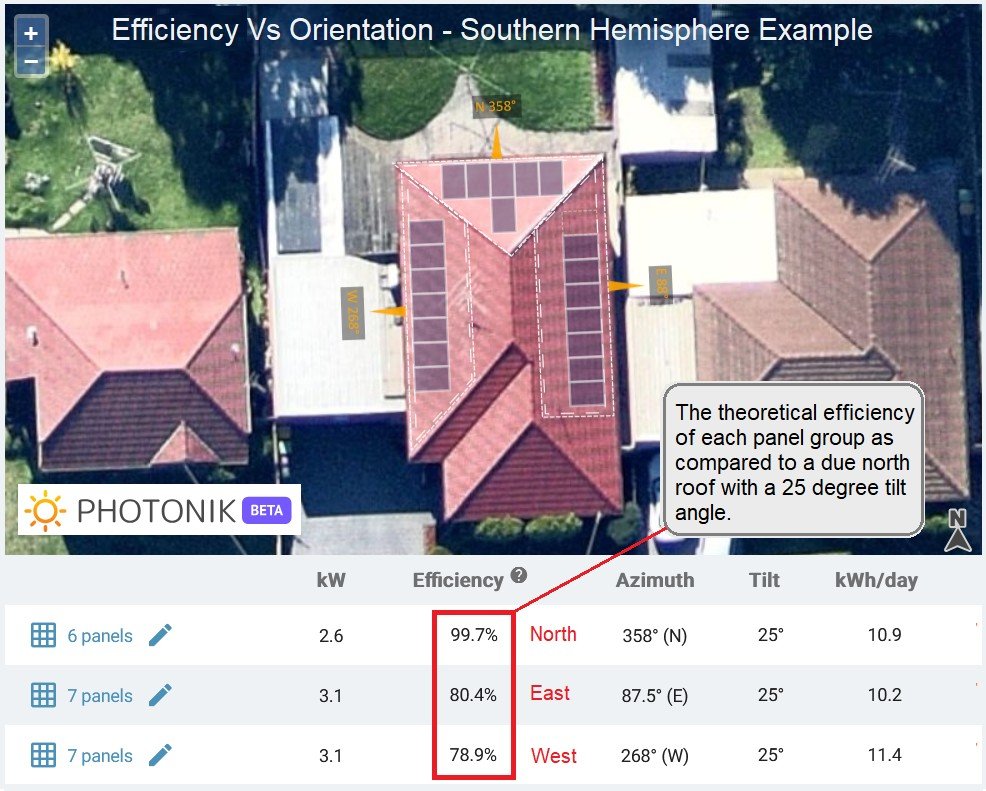

A correctly sized solar array is required to charge the battery while also supplying the loads. As explained in more detail below, you must ensure the solar array is large enough while taking into account local conditions, including average solar irradiance throughout the year (peak sun hours), shading issues, panel orientation and tilt angle, cable losses, and temperature derating (loss factors). Our Photonik solar calculator can help estimate solar generation throughout the year, depending on the panel orientation, location and shading losses.

Step 4 - Inverter selection

After steps 1 to 3 have been established, you can select a suitable solar inverter or MPPT Solar Charge Controller to match the solar array depending on the panel and string length, which will determine the string voltage. Always use a string voltage calculator to calculate the maximum and minimum string voltages to ensure the voltage does not exceed the input rating. Next, the primary hybrid or off-grid inverter must be selected to meet the continuous and surge loads, taking into account temperature derating and other loss factors explained in more detail below.

Step 5 - Backup generation source

After your solar system is sized correctly and you have estimated a suitable battery capacity, you need to consider a backup generation source such as a diesel generator, especially if you live in a temperate (colder) location. Even though a backup generator may only be needed for occasional use in winter, it needs to be sized correctly to power the loads and recharge the battery simultaneously, as explained in section 8. However, emerging technologies such as vehicle-to-load (V2L) can offset generator runtime in certain situations, as explained in our guide to using V2L in off-grid systems.

How to Design a hybrid or off-grid system

Modern hybrid & off-grid energy storage systems have many specifications to consider before selecting and sizing an appropriate inverter or battery system. Many different system types are available, including grid-interactive inverter-chargers, hybrid inverters, complete systems with integrated battery storage (known as a BESS) and AC battery systems. Here, we guide you through the process and highlight the key requirements that must be considered when selecting and sizing equipment.

Inverter power output - maximum continuous and surge ratings (kW)

Configuration - AC or DC-coupled?

Inverter charge rating (A)

Solar PV array sizing (kW)

Pass through power (A)

Battery selection and sizing (kWh)

Cable sizing and selection

Overcurrent protection - Fuses and breaker sizing

Software and energy management

Backup Power - Generators or V2L

1. Inverter Power ratings

Battery inverters, hybrid or off-grid, are available in a wide range of sizes determined by the continuous output power rating measured in kW or kVA. The inverter power rating depends on the inverter topology or design, the type of power conversion circuitry, whether it uses a transformer, the cooling system, and the operating temperature. Below are two main types of hybrid and off-grid inverters available.

Off-grid inverters use heavy-duty transformers, which are more expensive but provide high surge and peak power output and can handle high inductive loads. These inverters typically contain active fan-forced cooling systems to help maintain performance in high temperatures. As explained below, most of these inverters have integrated chargers and are grid-interactive, meaning they can also be used to create micro-grids or hybrid systems.

Hybrid inverters and AC-coupled battery systems generally use transformer-less inverters with 'switching transistors'. These compact, all-in-one inverters have lower surge and peak power output ratings but are more cost-effective because they combine the solar inverter (MPPTs) and battery inverter-charger into one integrated unit. They are also typically fully weather-rated, meaning they can be safely installed in more exposed locations, but direct sunlight should always be avoided.

Continuous Power rating

The inverter should be matched (sized) slightly higher than the loads or maximum demand of the appliances it will be powering. Due to temperature de-rating in hot environments, the inverter should be at least 1.2 times larger than the maximum continuous summer demand. Depending on the application, this is often the most important specification to be considered when selecting a hybrid inverter, especially when using a hybrid inverter as a backup power source for dedicated or essential loads. Whether the loads are inductive or resistive is also very important and must be taken into account.

Maximum Demand explained

Maximum inverter demand is the highest continuous load expected from the inverter, typically over a 30-minute period. If possible, the maximum demand should be based on data measured using a metering device. If load data is unavailable, maximum demand should be estimated based on selected loads in a load table, typically including the highest power rating loads and any other loads likely to be used simultaneously. The selection should be based on a thorough understanding of the load usage patterns to ensure accuracy.

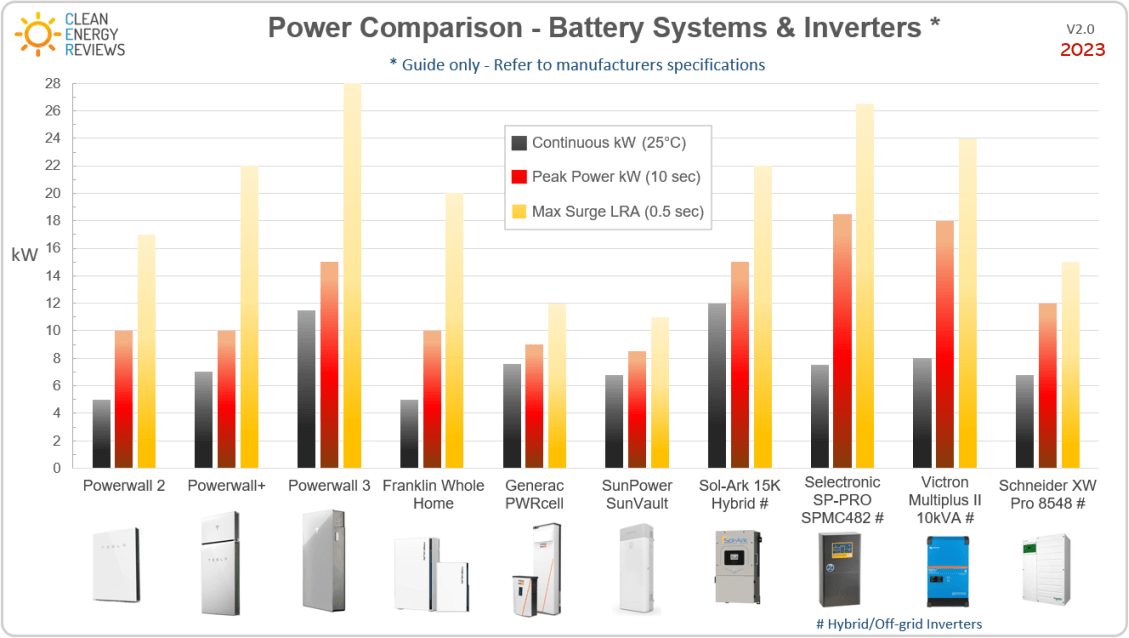

Comparison chart of the leading off-grid inverters with continuous and peak power ratings * (48V)

Inverter sizing in kW or kVA

Something to be aware of is whether the inverter power rating is listed in kW or kVA (kilo Volt-Amps). Kilowatts is generally the more accurate rating. This can be a little confusing when sizing an inverter for your needs as many manufacturers list the kVA rating due to being greater than the equivalent kW rating. The general conversion ratio used for kVA to kW is:

kVA x 0.8 = kW

5.0 kVA x 0.8 = 4.0 kW

For example, a 5.0 kVA inverter roughly equates to a 4.0 kW inverter power rating. Another example is a 3000VA (3kVA) continuous power output inverter, which generally only outputs 2400 Watts (2.4kW) continuously, so approximately 80% of the ‘apparent’ power rating.

Off-grid Inverter Sizing

For off-grid installations, the inverter sizing is critical and must be sized to meet the total load (maximum demand) under all conditions. As mentioned, temperature derating is especially important as the inverter output is derated (reduced) at higher ambient temperatures. For example, a 6kW inverter rated at 25°C may only output a continuous power of 4.8kW at 40°C. This derating factor must be taken into account, especially in warmer climates.

Example - Victron Energy Quattro datasheet showing the difference Continuous power output at various temperatures.

Inverter Surge or Peak Power Output

The peak power rating is very important for off-grid systems but not always critical for a hybrid (grid-tie) system. If you plan on powering high-surge appliances such as water pumps, compressors, washing machines and power tools, the inverter must be able to handle the high inductive surge loads, often referred to as LRA or Locked Rotor Amps.

The LRA rating is the absolute maximum amps an inverter can supply when starting a motor such as a compressor or large pump from a standstill. It's easier to understand the LRA rating as the maximum possible short-duration surge rating. Unlike the peak power rating, which can generally be sustained for up to 10 seconds, the absolute maximum surge or LRA output is usually less than 0.5 seconds. Not all inverter manufacturers will list the LRA rating, but it is often assumed to be 1.5 to 2 times the surge power rating. Refer to the manufacturer for clarification.

* Power rating comparison chart of the leading hybrid and off-grid inverters. To be used as a guide only - refer to manufacturer specifications for full details.

The amount of time the inverter can maintain the surge power output is also very important but can be misleading depending on how it is described by the manufacturer. For example, some inverters may specify the surge output of say 8kW, while others may specify 8kW for 60 seconds. When a surge time (in seconds) is not specified, the surge rating may only be sustained for 1 or 2 seconds. Generally, the high-end grid-interactive inverters have the highest surge ratings for the longest amount of time. The Selectronic SP PRO is known to have one of the highest surge ratings of any battery inverter on the market.

Backup Power

The chart above highlights that some battery systems have reduced or limited backup power when operating in backup or emergency supply mode (EPS). Depending on the battery used, this can be further limited by the battery capacity and battery output power rating. However, several systems & inverters do not have reduced power output in backup mode. The dedicated off-grid/hybrid inverters such as the Selectronic SP PRO and Victron Multiplus do not have any such limitations.

2. Configuration - AC or DC-coupled

As solar battery systems became larger and more advanced, AC-coupled systems became one of the best configurations due to low-cost, easy-to-install string solar inverters. Most modern off-grid AC-coupled systems use bi-directional inverters coupled with one or more compatible solar inverters. AC-coupled systems are generally more efficient during the day when there is high AC power demand, such as air-conditioning systems, modern kitchen appliances and pool pumps. However, high-voltage DC-coupled battery systems (HV) are becoming more popular with the growing range of advanced HV hybrid inverters on the market.

For more information, see our detailed article explaining the difference between AC & DC-coupled systems.

3. Inverter Charge Rating

The battery inverter max charge rating, measured in Amps, needs to be considered to ensure the battery bank capacity and inverter are ‘balanced’ correctly. Ie. In AC-coupled systems, ensure the inverter-charger has enough charging capacity to enable the battery to reach the absorption charge voltage. If the battery bank is too large and the inverter charge rating is too small, the battery will not achieve a complete charge cycle. This will result in unbalanced cells, poor performance, degradation and possible sulfation (if lead-acid batteries are used).

Most modern lithium battery systems can accept a high charge current and can be charged at a higher C rate. If an oversized solar array is used and the inverter charge rate is insufficient, the solar generation may be clipped (reduced), and the system will not perform as efficiently. DC-coupled solar can help overcome this issue as the solar array is directly connected to the battery system and not contained by the inverter charge rating.

Example: Selectronic Inverter spec sheet (SP PRO) highlighting the maximum charge rating in red.

4. Solar Array Sizing Guide

Once you have established the average daily energy consumption (kWh), the next step is to determine the solar array size in kW while taking into account the local solar irradiation and any shading losses. The battery capacity (kWh) should also be considered for off-grid systems when sizing the solar array. This is not straightforward, as there are many variables to consider.

Peak Sun Hours Explained

A general guide is to use the minimum peak sun hours (PSH) of your location in Winter. Peak Sun Hours are not the daylight hours but the combined hours when the sun's insolation adds to 1,000 W/m2. This is when your solar panels generate the most electricity, much like measuring the optimum time for solar generation in a specific area. The official PSH figures are unique for every location and are generally provided by meteorological organisations.

The winter Peak Sun Hours or PSH value is typically used to ensure the solar array is large enough to fully charge the battery bank during the shortest sunny day. For example, if you had an off-grid system with a 16kWh battery, you need to generate a minimum of 20kWh during the shortest day, assuming the daytime loads were very low. If the daytime loads are 10kWh, then you will need to generate as much as 30kWh on a sunny day in winter. You can use the Photonik solar design tool to determine how many kWh a solar array will produce throughout the year based on the local PSH, orientation and array tilt angle. Due to the relatively low cost of solar panels, oversizing the solar array is a common practice to ensure the battery is charged even during poor or intermittent weather. In off-grid systems, oversizing will help reduce backup generator runtime.

MPPT String Voltage

Accurately calculating the string voltages is critical when designing a solar array using string solar inverters or MPPT solar charge controllers. Solar systems must operate under a wide variety of weather conditions and climates, and the ambient temperature significantly affects the string voltage, which in turn impacts the system's performance, safety and reliability. You can use our free String Voltage Calculator to quickly determine the string voltage using the historical temperature data for your location.

Solar Size Limits

Hybrid inverters have integrated MPPTs (trackers) with solar size limits based on the string input voltage and current rating. Smaller hybrid inverters (4 to 6kW) are generally limited to 10kW of solar, while larger 10 to 12kW hybrid inverters can often accommodate solar arrays up to 20kW. In comparison, grid-interactive off-grid inverters such as the Selectronic SP PRO, SMA Sunny Island and Victron Multiplus can work with solar inverters or MPPT solar charge controllers in both AC and DC-coupled configurations. These systems technically have no solar size limits and can accommodate much larger solar arrays, which can be expanded later if needed.

AC-Coupled PV sizing

In AC-coupled off-grid systems, the solar inverter size is often limited by the inverter-charger power rating (kW). For example, the Victron Multiplus and Quattro inverter-chargers can only be AC-coupled with an inverter ratio of 1:1, meaning the solar inverter (AC) power rating must be the same as the inverter-charger AC power rating. A 5kW solar inverter is the largest size and can be AC-coupled with a 5kW Multiplus inverter charger. Note that more solar can be added using DC-coupling with a Victron system. Learn more about the Victron AC-coupling factor 1 rule. In comparison, the Selectronic SP PRO inverter ratio is 1:2, meaning it can have double the solar inverter AC capacity connected. For example, a 5kW SP PRO can be AC-coupled with 2 x 5kW Fronius solar inverters or one large 8.2kW Fronius inverter.

*IMPORTANT: When designing ‘managed’ AC-coupled off-grid systems using a solar inverter, the inverter must be compatible with the battery inverter to ensure the power output can be ramped down when the battery is full and the loads are low. For example, in Selectronic AC-coupled off-grid systems, a modified ‘Scert’ inverter is required to enable precision battery charge control using direct communication. In comparison, Victron and SMA AC-coupled off-grid systems generally use frequency shifting to manage the solar inverter’s power output. This is adequate but not as precise and can affect some sensitive electronic appliances.

DC-Coupled PV sizing

Unlike AC-coupled solar, DC-coupling does not have the same size limitations, and the solar array can be significantly oversized to allow for poor weather conditions and changes in seasonal solar irradiance. DC-coupling solar using MPPT solar charge controllers is a very efficient and reliable way of adding solar and has many advantages over AC coupling, explained in more detail below. See our detailed article, MPPT solar charge controllers explained, for more information about selecting and sizing DC-coupled solar charge controllers.

DC-coupling of solar using external MPPT charge controllers is not possible in most hybrid systems or all-in-one hybrid inverters. The reason is the battery must be managed by the hybrid inverter to ensure precise and safe battery charging. If an external charge controller is used, the hybrid inverter cannot control the MPPT when the battery is fully charged, and there is a serious risk of overcharging and damage. However, several off-grid systems, such as Victron and SMA, can be used as hybrid systems with both AC and DC-coupled solar, provided the charge controllers are compatible and connected correctly.

5. Inverter Pass-Through Power

The pass-through power feature (also referred to as an ‘integrated transfer switch’) enables the inverter to supply additional power from the grid or backup generator under high loads when the batteries are low or when solar energy is not available. The ability to pass through additional power from the grid (or generator in an off-grid system) can greatly simplify the installation by not requiring the separation of essential and non-essential loads.

Generally, only high-end grid-interactive & off-grid inverters can pass through additional power from the grid or auto-start and run a connected backup generator. Selectronic, Victron Energy, and Schneider electric inverter chargers all feature built-in transfer switches with pass-through power capability. SMA Sunny Island systems require an external contactor to be installed when grid-connected.

6. Battery Selection & Sizing

Before the release of affordable lithium battery systems, most battery inverters were designed to operate with the widely available lead-acid batteries (Gel, AGM & flooded). Lead-acid batteries are larger and heavier and can emit gases that require ventilation. In contrast, lithium-ion batteries are lighter, compact, more efficient, and safe to store inside a sealed enclosure. The vast majority of lithium battery manufactures now use Lithium Ferro (Iron) Phosphate or LFP cells due to the longer lifespan and high thermal stability. Some of the most popular LFP lithium battery systems, such as those from BYD, Pylontech, and EG4, are managed batteries with integrated battery management systems (BMS), requiring an inverter with compatible communications (CANbus network protocol) to operate.

On the other hand, numerous self-managed lithium LFP battery systems also feature a BMS but do not require communications with the inverter and will function much like a lead-acid battery system; these include Simpliphi PHI, Powerplus Energy, GenZ LFP, and Zenaji LTO battery systems.

Lithium battery comparison chart - See the full chart of the leading off-grid lithium battery systems

Lead-acid batteries

For off-grid systems, lead-acid batteries are still a well-proven and reliable technology with a lifespan of up to 15 years when sized and managed correctly. One of the biggest benefits of lead-acid batteries is that, unlike modern lithium batteries, they will not shut down at a low voltage or low SOC. This is important in emergency situations or when a backup generator fails or is not available.

Higher Battery Voltage = Increased efficiency

All hybrid and off-grid inverters are designed to use a specific nominal DC battery voltage, the most common being 48V. Since most lithium battery systems are 48V, this is not a problem. However, many small-capacity inverters use 12V or 24V, so these are only compatible with battery banks of the same voltage. Selectronic, SMA and Schneider have a range of high-end 48V hybrid/off-grid inverters, while Victron Energy and Outback Power supply both dedicated 12V, 24V & 48V off-grid inverters. High-voltage or HV battery systems from 150 to 500V are increasingly common for grid-tied home battery systems, and many hybrid inverters such as the SolarEdge StorEdge, Goodwe EH and Fronius GEN24 Plus all work with high-voltage battery systems. However, it’s worth noting that HV battery systems are not universal and are generally only compatible with a specific hybrid inverter.

Optimum Voltage for Off-grid Systems

For off-grid systems, 48V battery voltages offer many advantages over 12V or 24V batteries, particularly for larger systems. AS shown in the example below, 48V systems result in a reduced current draw for the same power output, leading to lower resistance, cable losses, and voltage drop. This enhances efficiency across all power conversion equipment, including inverters and MPPTs. Low voltage 12V battery systems are generally only suitable for small applications like RVs, caravans or sheds; 12V systems are not recommended for AC power draws exceeding 2000W due to the high current demands. Increased current in electrical systems requires much larger cable (conductor) sizes and can lead to greater heat generation, causing thermal expansion and contraction that can stress components and circuit boards, often resulting in electronic failures.

For example:

4000W @ 12 V = 333 Amps

4000W @ 24 V = 166 Amps

4000W @ 48 V = 83 Amps

48V battery systems offer numerous benefits compared to lower voltage systems, including more solar power per MPPT, which results in far greater solar capacity per MPPT in DC-coupled systems. Moreover, the reduced chance of failure as the higher voltage and lower current minimise the heating effect caused by resistance in connections and terminals. Finally, 48V systems have a significant cost advantage compared to 12V and 24V due to the higher number of options and increased competition; there are far more 48V battery options, which are generally cheaper than the equivalent (kWh) capacity lower voltage versions. Additionally, 48V inverters cost less per kW to purchase.

Benefits of 48V systems compared to 12/24V

More solar power capacity per MPPT due to reduced current

Enhanced efficiency by reducing voltage drop and associated losses.

Lower wiring costs with smaller gauge cables due to lower current.

Higher voltage and lower current minimize the heating effect in connections.

Reduces the risk of overheating and potential failure.

More options and increased competition - many 48V LFP battery options.

Reduced upfront cost - 48V inverters cost less per kW to purchase.

Battery Capacity - kWh

Modular, rack-mount lithium battery system

Battery capacity is measured in kWh (kilowatt/hours), or Amp-hours (lead-acid), which is the total energy a battery system can store. However, not all available capacity is usable depending on the battery type and specifications. Common Lead-acid deep-cycle batteries (AGM & Gel) should only be discharged to 20-40% of total capacity on a daily basis, whereas Lithium-ion and new-generation battery technologies can be discharged to 80-90% SOC. Therefore, the battery chemistry and capacity must be carefully selected to cater to the user’s energy requirements.

Hybrid Vs. Off-grid Example - For a typical grid-connected home with peak (evening) energy use of 10kWh from 5 pm until midnight, a 12-15 kWh lithium battery would be sufficient. However, for off-grid systems, the battery system will need to store enough energy for several consecutive days of bad weather. With an average (efficient) home using 10-15 kWh over a whole day, this will require a much larger, more expensive 30-60 kWh battery system, depending on the days of autonomy required and the size of the solar array.

How to Size an Off-Grid Battery System

To correctly size an off-grid battery system, several factors need to be considered, including the daily load (kWh), inverter power rating, peak loads, and number of days of autonomy. Below are the steps to ensure the battery system is sized correctly to match these requirements.

Calculate the Daily Load Requirements:

Determine the average daily energy consumption in kilowatt-hours (kWh) per day using a load table. This includes all appliances, loads and devices that will be powered by the system. Generally, the winter load is used when the days are shorter, and the loads are typically higher.

Determine the Number of Days of Autonomy:

Decide how many days your battery system should be able to sustain your loads without recharging from solar or other sources (days of autonomy). This is crucial for periods with limited sunshine or during inclement weather. A general guide is two days for lithium battery systems, while less efficient lead-acid batteries are generally sized for three or four days.

Battery Storage Capacity (kWh):

Size the battery system based on the total energy required per day (kWh/day) multiplied by the number of days of autonomy desired. This gives the total energy storage capacity needed in kWh.

Required Battery Capacity = Daily Load (kWh/day) × Days of Autonomy

Peak Demand Loads and Power Requirements

Using a load table, you can estimate the peak power demand (kW) your inverter and battery system must handle simultaneously. Inverter losses must be taken into account when calculating the peak DC current demand (A). For example, if your peak demand loads were 8500W AC, and the 48V inverter efficiency was 92% (8% loss), then the peak DC battery demand would be calculated as follows:

8500 W × 1.08 = 9180 W (DC load)

9180W / 48V = 191 Amps (Battery current)

Battery Output Power Rating:

The battery must be sized to handle both the peak load demand and the total energy consumption of the connected devices. Ensure it has sufficient power out (in Amps) to meet peak demand without overloading the battery system or the main fuse isolator/breaker. If the number of batteries cannot support the maximum load demand, more batteries must be added, or alternatively, a battery system should be chosen that can meet the power demand.

Also, ensure the main battery cables are rated to carry the maximum current with at least a 20% safety factor to allow for higher temperatures.

Modular, Rack-Mount Lithium Battery Systems

Modular lithium battery systems consist of individual battery modules that can be interconnected to scale up capacity as needed. These systems allow flexibility in design and future expansions. They can accommodate changes in energy consumption without requiring a complete overhaul of the system. Using rack-mount lithium battery systems, you can accurately size your off-grid battery system to meet current needs while allowing for future expansion and changes in circumstances over time.

7. Cable Sizing

Proper cable sizing is critical in solar and battery installations for ensuring system efficiency, safety, and reliability. The cables used must safely handle the expected current, minimise losses, and be protected from potential overcurrent situations. As explained in this section, below are the three key steps to correctly sizing cable:

Calculate the maximum current draw in the cable.

Determine the total cable length and cable path - inside conduit, walls or in the open.

Selecting the correct cable based on the current draw, current carrying capacity & temperature rating.

Calculating Maximum Current Draw

When sizing battery cables, the first step is to determine the maximum current that will flow through the cable. In off-grid systems, this calculation is typically based on the inverter’s maximum continuous power rating, but the peak inverter rating must also be taken into account. We use the system’s DC voltage using Ohm’s law to do this.

I = P/V

I: Current (Amps)

P: Power (Watts) — the inverter’s rated output

V: Voltage (Volts) of the DC system

For example, if an inverter is rated at 5,000 W and the DC system operates at 48 V, the maximum continuous current draw is: I = 5,000 W / 48 V = 104 A *

(*) This calculation provides the baseline for selecting cables that can safely handle the current without excessive voltage drop. However, if the inverter peak current is 10,000W watts, the cable must be rated to carry up to 208A.

Cable Gauge Sizes: AWG Vs mm²

Cables are commonly sized in either American Wire Gauge (AWG) or by cross-sectional area in mm². Understanding both systems is helpful, as manufacturers and installation standards may use different units. Below is a comparison table comparing standard AWG Sizes to the equivalent Cross-Sectional Area (mm²).

10 AWG = 5.3 mm²

8 AWG = 8.4 mm²

6 AWG = 13.3 mm²

4 AWG = 21.2 mm²

2 AWG = 33.6 mm²

1 AWG = 42.4 mm²

1/0 AWG = 53.5 mm²

Note: These values are approximate and may vary slightly based on the cable type and manufacturer.

Current Carrying Capacity (CCC)

Double insulated flexible DC cable

The current carrying capacity, often referred to as ampacity, is the maximum current a cable can safely conduct without overheating. Matching the cable’s ampacity to the calculated maximum current draw ensures that the cable operates within safe thermal limits, reducing the risk of insulation degradation or fire hazards. Factors main that affect CCC include:

Cable Cross-Sectional Area: Larger cables (with greater mm² or lower AWG numbers) can carry more current.

Installation Conditions: Ambient temperature, conduit fill, and cable bundling affect heat dissipation. For example, cables enclosed in walls, conduits, or within insulation will run hotter than cables mounted on a wall.

Material and Construction: Different conductor materials and cable designs offer varying heat resistance. For example, flexible (multi-strand) cables offer a greater CCC compared to regular building wire used in AC applications.

Insulation Temperature Rating

Insulation temperature rating refers to the maximum continuous operating temperature at which a cable’s insulation can perform reliably without degradation. This is a crucial factor because elevated temperatures can affect the cable voltage drop (efficiency), its lifespan and the system's overall safety. Generally, the minimum temperature for power systems at which a cable should be rated is 90°C (194°F).

V90 Rated Cable: This cable has insulation designed to operate at temperatures up to 90°C (194°F). It is suitable for many standard applications with moderate ambient temperature and operating conditions.

V110 Rated Cable: Cables with insulation rated for up to 110°C (230°F) are ideal for high-temperature environments or applications where cables may be bundled closely together, limiting heat dissipation. This is the preferred cable for battery installations, especially where high continuous current flow is expected.

Double-insulated flexible cables (often used in welding applications) are typically rated at a minimum of 110°C (230°F) and are an excellent option for battery cables due to their high quality and durability. The flexibility also allows for bending, making them ideal for installations where cable routing is tight. DC welding generally has a very high insulation rating (from V110 up to V300) and improved safety, as the double insulation provides an extra layer of protection.

Online cable size calculators

Online cable size calculators are invaluable tools for both professionals and DIY enthusiasts when designing solar and battery systems. These calculators allow users to quickly input key parameters—such as maximum current draw, system voltage, cable length, and permissible voltage drop—to determine the optimal cable size for a given installation. By automating complex calculations, these tools help ensure compliance with safety standards and efficiency requirements. Note different countries and jurisdictions may have different cable standards and requirements.

Below are links to some of the best online cable calculators:

jCalc - Australian AS/NZS3008 cable size calculator - https://www.jcalc.net/cable-sizing-calculator-as3008

Southwire - North American Wire Gage Calculator - https://www.southwire.com/calculator-vdrop

Elandcables - International and British standards - https://www.elandcables.com/cable-calculator

Example: An off-grid system with two overcurrent protection (MCCB) devices sized correctly to protect the cable.

8. Cable Overcurrent Protection

Overcurrent protection is a critical safety feature in DC solar and battery systems. It prevents cables and components from experiencing currents beyond their safe operating limits, reducing the risk of overheating, equipment damage, and even fire. The rating of the overcurrent protection device (measured in amperes) must be carefully selected in relation to the cable size. Typically, the protection device is chosen to match or slightly exceed the calculated maximum current draw, ensuring that the cable is not exposed to dangerous currents under fault conditions.

Why is overcurrent protection so important?

Safety: Overcurrent protection devices (OCPDs) such as fuses and circuit breakers disconnect the circuit when the current exceeds safe levels. This quick response is essential to prevent excessive heating and potential fire hazards.

Equipment Protection: Sensitive components in solar and battery systems—like inverters and charge controllers—are safeguarded against damaging current surges.

Ease of Maintenance: Properly rated OCPDs help isolate faults quickly, making troubleshooting and routine maintenance safer and more straightforward.

Types of Overcurrent Protection Devices

HRC Fuses (High Rupturing Capacity Fuses)

HRC fuses were the industry standard in DC solar and battery applications for many years. They are designed to interrupt extremely high fault currents, ensuring the circuit is safely broken. Before modern MCCBs became more common and cost-effective, HRC fuses were the preferred solution for overcurrent protection. Their proven track record in high-demand applications means they remain a viable option in specific situations where fusing and maximum fault interruption are required. However, they have a very poor IP (Ingress Protection) rating, meaning they are susceptible to dust and moisture ingress, which can cause corrosion, leading to increased resistance and overheating.

Advantages:

High Interrupting Capability: Able to handle very high short-circuit currents, making them highly reliable under severe fault conditions.

Fast Acting: Their rapid response helps instantly disconnect the circuit when an overcurrent event occurs.

2. MCCBs (Molded Case Circuit Breakers)

Over recent years, MCCBs have become more popular due to their ease of use and reusability. They offer adjustable trip settings and can be reset after a fault, which minimizes downtime and maintenance costs. When installed inside a compatible enclosure, they offer a very high ingress protection rating, up to IP65, allowing safe installation in exposed locations.

Advantages:

Resettable: Unlike fuses, which must be replaced after tripping, MCCBs can be quickly reset, which is beneficial in systems where service interruptions need to be minimized.

Adjustable Trip Settings: Allowing for precise calibration based on the specific requirements of the installation.

High IP rating * - Very good protection against dust and moisture for long-term reliability and performance. (* When installed in a compatible enclosure)

Increased safety * - No exposed terminals or connections for improved safety. (* When installed in a compatible enclosure)

Matching Overcurrent Protection to Cable Size

The chosen fuse or circuit breaker must have a rating that protects the cable by ensuring it does not carry current above its current carrying capacity (CCC). Typically, the OCPD rating is set to match or slightly exceed the calculated maximum current draw (using I = P/V) to provide a safety margin. An operating safety margin should be considered; generally, 20 to 25% additional overcurrent protection should be added so that under normal operating conditions, the device remains inactive. It should only trigger under fault conditions where the current significantly exceeds the cable’s capacity.

9. Software and Energy Management

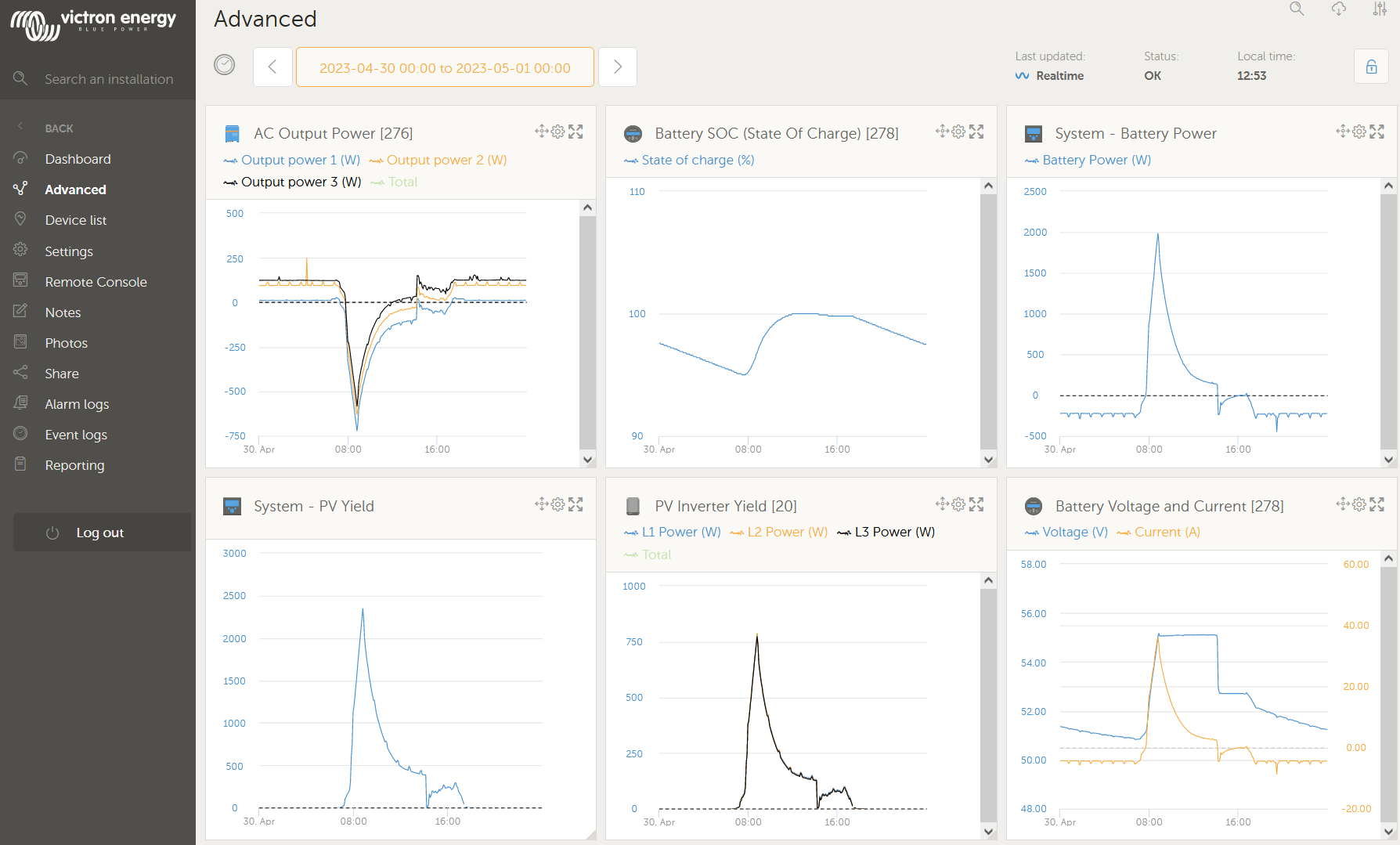

A high level of power management and system monitoring is required to enable hybrid or off-grid power systems to optimise energy use and prolong battery life. The software used to run hybrid and off-grid systems thus requires advanced energy management and monitoring capabilities, and this is where the high-end grid-interactive inverters shine. These powerful inverters, such as those from Victron Energy, Selectronic, Schneider Electric and SMA, have the most advanced software packages with built-in control systems, relays and digital inputs and outputs. These systems also incorporate specialised battery monitoring and temperature sensors to prolong battery life and optimise charging with lead-acid or VRLA battery banks.

The Victron Energy VRM monitoring and control software is one of the most advanced and user-friendly systems available, offering high-level data and remote access for both installers and customers.

Selectronic SP.Link software is used to configure the SP PRO inverter-charger. This advanced software package has 8 system priority settings enabling multiple operating modes depending on the various inputs, outputs and battey SOC. Click to enlarge

Example of logged data from a Redback technologies hybrid inverter - Image credit Redback Portal

Third-party system monitoring

For additional monitoring and control, third-party add-on energy monitoring systems like Reposit Power and Solar Analytics can provide more advanced remote monitoring and intelligent control features.

Popular add-on remote monitoring and energy management systems

Most hybrid systems with built-in battery storage (BESS systems) also utilise advanced energy management systems and sensors however, some of the low cost all-in-one hybrid inverters have limited capabilities which can result in less efficient use of stored energy.

Virtual Power Plants and Distributed Energy Resources

The Switchdin Droplet designed for DER and VPP.

Larger scale micro-grids and virtual power plants, or VPP’s, require unique technology designed to integrate and manage distributed energy resources (DERs). Switchdin has emerged as one of the leaders in this space, with the Droplet controllers allowing integration and control of DERs.

10. Backup Generators

Regions with short winter days, poor weather or snow cover, make it difficult to power an off-grid home entirely from solar energy throughout the year. In this case, a backup power source is required. If you are lucky enough to have a running stream, Micro hydro can be a viable option. However, most households need a backup generator for a few days or weeks. If you have a well-insulated and efficient home and an oversized solar array (without snow cover), you may be able to do without a backup generator by being conservative with your energy usage and load shedding (turning off some non-essential loads such as hot water for short periods of time).

People living off-grid in temperate and cooler climates will need a backup generator, the most common type being the diesel auto-start variety. A two-wire auto-start feature will enable the off-grid inverter to automatically control and manage the generator operation based on the programmed control settings.

Generator Efficiency and Runtime

A typcial, modern backup auto-start diesel generator

As a general rule, all combustion (diesel/petrol) generators are most efficient if operated at 70 to 80% load. For example, if you have a 10kVA generator, you would want to operate at a load of 7kVA to 8kVA, which equates to 6 - 7kW. Operating at the optimal load will dramatically improve fuel efficiency and reduce runtime. This will also improve the generator's lifespan and ensure it is not overloaded and damaged, or underloaded, which can cause premature wear and increased emissions.

Another factor you need to consider is the battery bank type, capacity and overnight load (kWh). For example, if you have a lithium battery, you may only need to run the generator for long enough to charge the battery with enough energy to get you through to the next day. In this situation, you would not charge the battery 100% or even 90%. You might only need to charge 60% state of charge to get you through to the following day, especially if the weather forecast is good. When charging lead-acid batteries, charging the battery to 100% using a generator is not recommended, as the charging current required for the last 10% of charging is very low and will severely underload the generator for a prolonged time.

Backup power using Vehicle-to-load (V2L)

Vehicle-to-load (V2L) technology is also being explored in off-grid systems, potentially reducing or replacing backup generators in certain scenarios. An electric vehicle (EV) equipped with V2L could serve as a backup power source due to its large battery capacity, typically 70kWh, around double that of an average residential off-grid solar system. This large capacity allows EVs with sufficient V2L capability to store surplus solar energy and provide backup power when needed.

The feasibility of using V2L hinges on two main factors:

The EV must generally have sufficient battery capacity for backup power, which may be constrained if it is regularly used for long-distance travel. Alternatively, if the EV is used for shorter trips and remains parked at home during the day, a portion of its battery capacity could be allocated to backup power.

The effectiveness of using V2L is based upon adequate solar availability, particularly in winter, when solar energy may be insufficient due to factors like shading, snow cover, or poor weather. Oversizing the solar array can mitigate these challenges by ensuring ample energy production for household needs and EV charging. Learn more in our detailed V2L explained article.

Hybrid & off-grid inverter comparison charts

See our detailed inverter comparison charts: