Latest Solar Panel Technology

Over the last few years, there has been an explosion in new solar technology, with next-generation panels featuring a variety of advanced PV cell designs and innovations that help boost efficiency, reduce degradation, and improve reliability. While some of the recent advancements, including micro-busbars and gapless cell architectures, have been adopted by many manufacturers, other innovations and combinations, like hybrid back-contact and tandem silicon-perovskite cells, are very new. In this article, we uncover the latest technologies and examine how these new solar innovations increase efficiency, improve overall performance and increase the lifespan of a solar panel.

Latest Solar Cell Technologies in 2025

Solar cell technology has seen significant advancements in the last two years, with several innovations reaching commercial production. Among these, perovskite-silicon tandem cells have emerged as a promising development, achieving cell efficiencies of up to 30% while maintaining cost-effectiveness in manufacturing. Additionally, next-generation bifacial solar panels, which capture sunlight from both sides using TOPcon cells, have gained traction, allowing for improved energy yield in various installation environments.

Most panel manufacturers offer a range of models, including regular entry-level options and more advanced high-efficiency varieties featuring new technologies such as high-density cells, micro-wire busbars and rear-side passivation. Below is a list of the leading PV cell technologies used today:

Perovskites - Perovskite-silicon tandem cells

HJT - Heterojunction tandem cells

TOPCon - Tunnel Oxide Passivated Contact cells

Gapless Cells - High-density cell construction

Micro-BB & 0BB - Micro-wire busbars and Zero Busbar cells.

Split cells - half-cut and 1/3 cut cells

IBC - Interdigitated Back Contact cells

Hybrid BC - Hybrid forms of Back-Contact cells

These innovations, and more explained in detail below, offer various efficiency improvements, shade tolerance, and increased reliability. Many manufacturers offer up to 25-year product warranties and 25- to 40-year performance warranties. However, with all the new panel varieties available, it is worth doing some research before you invest in a solar installation. In our quality solar panel review article, we explain how to select a reliable solar panel and further highlight the best quality manufacturers on the market.

Solar Panels Featuring the Latest Technologies

Below is our list of panels featuring the latest advancements in PV technology rated according to the cell technology, efficiency improvements, performance, and innovations. For the most efficient solar panels, see our detailed solar panel efficiency review.

| Make | Leading Model* | Cell Type | Cell Technology* | Max Efficiency* |

|---|---|---|---|---|

| Aiko | Black Hole Series | N-type | Half-cut Back-Contact 18BB | 23.8% |

| REC | Alpha Pure RX | N-type | Half-cut HJT lead-free Gapless 20BB | 22.6% |

| SPIC | Andromeda 3.0 | N-type | Half-cut IBC-TOPcon MBB Gapless | 22.8% |

| Longi Solar | Hi-MO 6 Scientist | N-type | Half-cut Hybrid Back-Contact MBB | 23.0% |

| Trina Solar | Vertex S+ | P-type | Half-cut TOPcon MBB | 22.5% |

| JinkoSolar | Tiger NEO | N-type | Half-cut TOPcon Gapless | 22.5% |

| Panasonic | EverVolt H | N-type | Half-cut HJT MBB | 22.2% |

| Canadian Solar | CS6R-H-AG | N-type | Half-cut HJT MBB | 22.5% |

| Futura Sun | FU 360M Zebra | N-type | IBC MBB Half-cut | 21.3% |

* Leading model using the most advanced PV cells currently offered by the manufacturer

HJT = Heterojunction cells, MBB = Multi busbars, Gapless = High-denisty cells, Ga-doped = Gallium doped silicon

Learn about the difference between N-type and P-type solar cells here.

Solar Panel Efficiency

Solar panel efficiency is one of several important factors and is dependent upon both the PV cell type and panel technology. Average panel efficiency has increased considerably over recent years from around 16% to well above 22% as manufacturers incorporate the latest cell technologies and innovations.

The rear side of a SPIC panel featuring N-Type IBC gapcell cells

At present, the world's most efficient solar panels are manufactured using HJT and IBC N-type monocrystalline silicon cells and achieve efficiency levels above 23.5%. While HJT and IBC N-type cells are more expensive to manufacture, the higher upfront cost is outweighed by the increased efficiency, improved performance at higher temperatures and minimal light-induced degradation (LID), which means much higher energy yield over the life of the panel.

Sunpower, Aiko, SPIC and Recom are currently the leading manufacturers using IBC cells. However, the latest REC, Longi, Huasun, Trina, and Canadian Solar panels also utilise more efficient N-type heterojunction (HJT) and TOPCon cells. Panels featuring HJT cells offer an extremely low power temperature co-efficient, which means they can outperform even IBC cells under certain conditions. See the complete list of the most efficient solar panels.

High-Temperature Performance

Thermal infrared image of a solar array

The power temperature coefficient is the amount of power loss as cell temperature increases. All solar cells and panels are rated using standard test conditions (STC - measured at 25°C) and slowly reduce power output as cell temperature increases. Generally, the cell temperature is 20-35°C higher than the ambient air temperature, which equates to an 8-14% reduction in power output.

Power temperature coefficient comparison - Lower is more efficient

Polycrystalline P-type cells - 0.4 to 0.43 % /°C

Monocrystalline P-Type cells - 0.35 to 0.40 % /°C

Monocrystalline N-type TOPcon cells - 0.30 to 0.32 % /°C

Monocrystalline N-type IBC cells - 0.27 to 0.30 % /°C

Monocrystalline N-type HJT cells - 0.25 to 0.27 % /°C

Monocrystalline N-type cells such as TOPcon, which are now widely used by many leading manufacturers, have an improved temperature coefficient compared to traditional Mono and Poly P-type cells used for much of the last decade. Monocrystalline IBC or Interdigitated Back Contact cells, described in more detail below, have a much lower temperature coefficient of -0.30% /°C compared to standard polycrystalline and monocrystalline cells. However, the best-performing cells at elevated temperatures are the heterojunction (HJT) cells, such as those from Panasonic and REC, which we describe in the last section of this article.

Perovskite Solar Cells

A prototype perovskite solar cell - Image credit Tandem PV

Perovskites have become the most talked about solar cell technology as they emerge from the labs into small-scale production. But despite the fanfare, the first commercial-scale solar farm featuring Perovskite panels was only installed in late 2024 and is currently under trial by Oxford PV. Perovskite solar cells have attracted significant attention since the early 2010s due to their low cost and ease of manufacture compared to silicon-based cells. However, despite the large amount of research and development into perovskite cell technology over the last 15 years, they have still not (quite) reached mass production. However, this might change in 2025.

Technology & Efficiency

The term "perovskite" refers to a specific crystal structure first discovered in the mineral calcium titanium oxide (CaTiO3) in the 19th century. While the first Perovskites were promising, their efficiency was very low. By 2012, the efficiency had risen to over 10%, but it only took a decade of research before the cell efficiency reached a staggering 30% in a lab environment. Unlike Silicon, which has a maximum cell efficiency of 30%, a combination silicon-perovskite's theoretical maximum cell efficiency has been calculated at an incredible 43%.

Perovskite solar cells operate similarly to traditional silicon-based solar cells, converting sunlight into electricity through the photovoltaic effect. The manufacturing process of perovskite cells is also very different from silicon cell production. Unlike silicon wafers, which require advanced production facilities, perovskites can be made using simple solution-based processes, enabling far lower fabrication costs and more straightforward manufacturing techniques. Techniques such as spin-coating, inkjet printing, and doctor blading are often employed to deposit perovskite layers onto substrates.

Perovskite & Silicon, A Powerful Combination

Silicon–perovskite tandem cells are beginning to enter the market as they merge silicon's proven, long-lasting performance with the efficiency-boosting potential of perovskite materials. Manufacturers can enhance overall efficiency by stacking a perovskite layer on top of a silicon cell without sacrificing the reliability of silicon. In contrast, while showing impressive efficiency in lab settings, pure perovskite cells still face significant challenges, such as long-term stability, environmental durability, and scalable manufacturing processes. The two main methods used to combine silicon and perovskites are Tandem and monolithic.

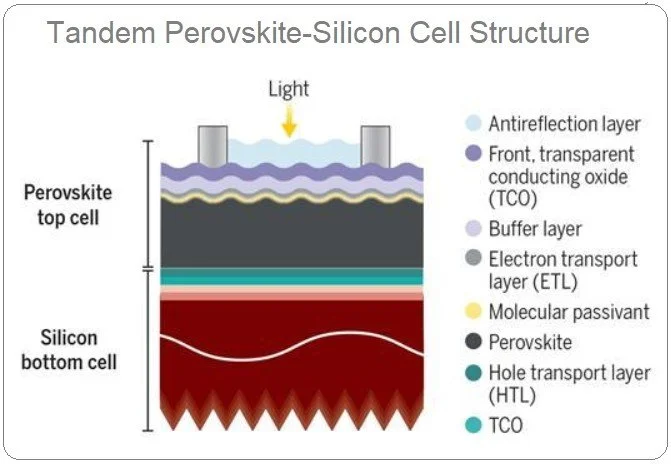

Tandem Cells

The primary manufacturing technology used is creating a tandem perovskite-silicon cell structure, where a thin layer of perovskite is deposited on top of a silicon base, allowing the perovskite to absorb high-energy visible light while the silicon absorbs lower-energy infrared light, effectively capturing a broader spectrum of sunlight and increasing overall efficiency.

Monolithic Cells

A perovskite-silicon monolithic cell is a type of cell where a thin layer of perovskite material is directly integrated into a silicon wafer, creating a single, unified structure (monolithic) where both materials work together as a tandem cell to harvest light more efficiently than either material alone; essentially, the perovskite acts as a top cell absorbing high-energy light, while the silicon bottom cell captures lower energy photons that pass through the perovskite layer.

Silicon–Perovskite Tandem Cells

A typical Tandem Perovskite-silicon solar cell structure - Image Credit: Stefaan De Wolf and Erkan Aydin

Silicon–perovskite combination (tandem) solar cells are designed with a multi-layered structure that optimizes the absorption of different parts of the solar spectrum. In these cells, a thin perovskite layer is deposited on top of a silicon sub-cell. The perovskite material, with its wider band gap, is engineered to efficiently absorb high-energy photons—typically from the blue and visible regions of the spectrum. In contrast, the underlying silicon cell has a narrower band gap, making it more suitable for capturing lower-energy photons in the red and near-infrared range that pass through the perovskite layer.

This layered approach takes full advantage of the fact that sunlight spans a broad range of energies. A single material with one fixed band gap can only convert photons with energies above that threshold, but by combining two materials with complementary band gaps, a tandem solar cell can convert a much larger portion of the incident solar spectrum into electrical energy. Essentially, the perovskite layer filters and converts the high-energy part of the spectrum, while the silicon layer handles the lower-energy light, leading to improved overall efficiency.

Moreover, these sub-cells are typically connected in series. This means that while the current generated by each cell is the same, their voltages add together, resulting in a higher overall output voltage for the tandem cell. However, this series connection also requires careful matching of the current produced by each sub-cell; if one cell generates significantly less current than the other, it can become the bottleneck that limits the performance of the entire device. As a result, optimizing both the band gap energies and the material quality is crucial for achieving a well-balanced and efficient tandem solar cell.

Stability Issues

Despite their promising performance and cost-effective production, perovskite solar cells still face several challenges that must be addressed before widespread commercialisation.

Stability: One of the major concerns is the stability of perovskite materials. Factors such as moisture, heat, and UV radiation can lead to degradation over time, significantly affecting the lifespan and reliability of the solar cells.

Scalability: While lab-scale devices have shown impressive efficiencies, scaling up production while maintaining performance and stability presents a challenge. Ensuring that large-area modules perform comparably to small samples is essential for commercial viability.

Regulatory Acceptance: As a relatively new technology, perovskite solar cells must navigate regulatory frameworks to gain acceptance in various markets. Rigorous testing and standardisation will be necessary to assure performance and safety.

While perovskite solar cells represent a significant advancement in photovoltaic technology, addressing these issues is imperative for future deployment in the renewable energy landscape. Ongoing research aims to rapidly mitigate these challenges and enhance the viability of perovskite solar cells for commercial applications. It appears that 2025 and 2026 will see the emergence of silicon-Perovskites as many of the leading manufacturers develop trial production facilities and start verifying commercial-scale systems.

Multiple Busbars - MBB

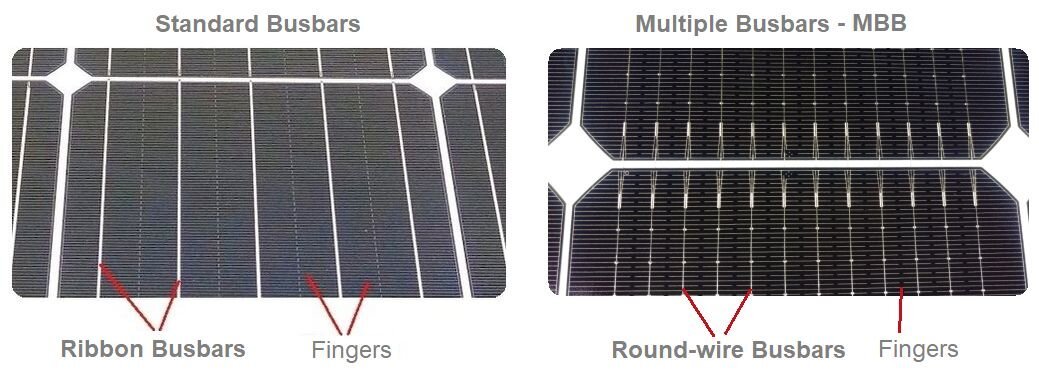

Small silver metallic fingers across each cell transfer current to the busbars. More recently, many manufacturers have moved from traditional ribbon busbars to multiple-wire busbars or MBB.

Busbars are thin wires or ribbons which run down each cell and are visible on most solar panels. Busbars perform two main functions, they collect the electrons from the small metallic fingers on the cell surface, and interconnect the front of the cell to the rear side of the adjacent cell creating a circuit throughout the panel. As PV cells became more efficient they generated more current and over recent years most manufacturers moved from 4 or 5 standard ribbon busbars to 9 or more multi-busbars (MBB). Some larger format cells, such as the 210mm cells developed by Trina Solar, have 12 busbars while the REC Alpha range has an impressive 16 micro busbars.

Multi-busbar compared to a standard ribbon busbar - Image credit Trina Solar

An additional benefit of more busbars is if a cell micro-crack occurs due to impact, heavy loads or people walking on panels, more busbars help reduce the chance of the crack/s developing into a hot spot as they provide alternative paths for current to flow.

LG was the first manufacturer to use round micro-wire busbars on the Neon 2 range of panels. LG called this 'Cello' technology which stands for 'cell connection, electrically low loss, low stress and optical absorption enhancement'. To translate, the Cello multi-wire technology lowers electrical resistance and increases efficiency.

Split Modules with Half-Cut Cells

Over the last few years, most leading manufacturer’s have shifted to using half-cut or half-size cells rather than the traditional full-size square cells. The square cells are laser cut in half and assembled into two groups of cells (upper and lower) that work together in parallel. This cell configuration has multiple benefits including increased efficiency due to lower resistive losses through the bus bars as each group of cells operates at the same voltage but half the current. The lower current also results in lower cell operating temperatures helps reduce the potential formation and severity of hot spots due to localised shading, dirt or cell damage. Additionally, since each group of cells is half the size, the busbar distance is reduced by half which means smaller busbars can be used resulting in less busbar shading losses and increased efficiency.

More recently, a number of manufacturers such as Trina Solar have started producing extra-large 210mm square cells which can be cut into three sections, known as 1/3-cut cells. These large format cells are used to produce high-powered panels up to 600W.

The Hanwha Q Cells Q.Peak Duo G6 panel uses half cut mono PERC cells with 6 round wire busbars

Half-cuts cell Improve shade tolerance

One of the greatest benefits of split-cell panels is when the are partially shaded. If the upper or lower section of the panel is shaded it does not affect the performance of the unshaded section. This is due to the two sections, or groups of cells, being connected in parallel and acting much like two small individual panels. During partial shading on the upper or lower section, the voltage is maintained and current is reduced by 50%, resulting in far better system performance when partially shaded.

Half-cut solar cells are used in split-cell panels to increase efficiency and improve performance in partially shaded conditions.

High-density Cells

To further boost panel efficiency manufacturers started introducing techniques to eliminate the vertical inter-cell gap between cells. Removing the standard vertical 2-3mm gaps between cells results in more of the total panel surface area being able to absorb sunlight and thus generate power which in turn increases total panel efficiency. This might sound like a relatively simple modification but the small gap provides space for the busbars to bend and interconnect the cells from the front side of one cell to the rear side of the adjacent cell.

Reduced cell gaps to increase cell density - Image credit Trina Solar

There are several techniques being developed to minimise or eliminate the intercell gap with the most common being to simply reduce the gap from around 2mm to 0.5mm as some space is still needed for the busbar interconnection. Traditional large ribbon busbars required several millimetres of space to bend between the front and rear of the cells. However, the transition to using much smaller multi-busbars has enabled the gap to be reduced significantly.

Increasing efficiency using Tiling Ribbon cell technology to remove the inter-cell gap - Image credit Jinko

To achieve this JinkoSolar developed what the company refers to as Tiling Ribbon or TR cells. Tiling Ribbon technology eliminates the inter-cell gap by slightly overlapping the cells and using a compression joining method. Tiling ribbon cells also dramatically reduces the amount of solder required which reduces the amount of silver needed making the panels both cheaper and more environmentally friendly.

Back Conact - IBC Technology

The rear side of a Sunpower 'Maxeon' IBC cell showing the fine metal grid conductors which improves efficiency, helps reinforce the cell and prevents micro-cracking.

IBC or Interdigitated Back Contact cells have a grid of 30 or more conductors integrated into the rear side of the cell, unlike traditional cells which have 5 to 6 large visible ribbon busbars and multiple fingers on the front side of the cell. The most obvious problem with the more common front exposed busbar design is they partially shade the cell and reflect some of the light photons which reduces efficiency. IBC cells don't suffer this problem and as a bonus look much 'cleaner' with no exposed busbars.

IBC silicon cells are not only more efficient but much stronger than conventional cells as the rear layers reinforce the whole cell and help prevent micro-cracking which can eventually lead to failure. Sunpower uses a high-grade, solid copper IBC rear foundation layer on their patented 'Maxeon' cell design along with a highly reflective metal mirror-like surface to reflect any light which passes through back into the cell. The rear side of the 'Maxeon' IBC cell shown below is extremely tolerant to stress and bending, unlike conventional cells which are relatively brittle in comparison.

N-type Solar Cell Technologies

While P-type PERC cells boosted efficiency and were the talk of the solar world from around 2018 until early 2024, N-type monocrystalline cells emerged as the most efficient and reliable solar cell technology in 2025. The first type of solar cell developed in 1954 by Bell Labs used an N-type doped silicon wafer, but over time, the more cost-effective P-type silicon became the dominant cell type, with over 80% of the global market in 2017 using P-type cells. Lower cost was the main driving factor behind P-type silicon, but now N-type production has improved dramatically and become the dominant player as manufacturing costs are reduced and efficiency increases.

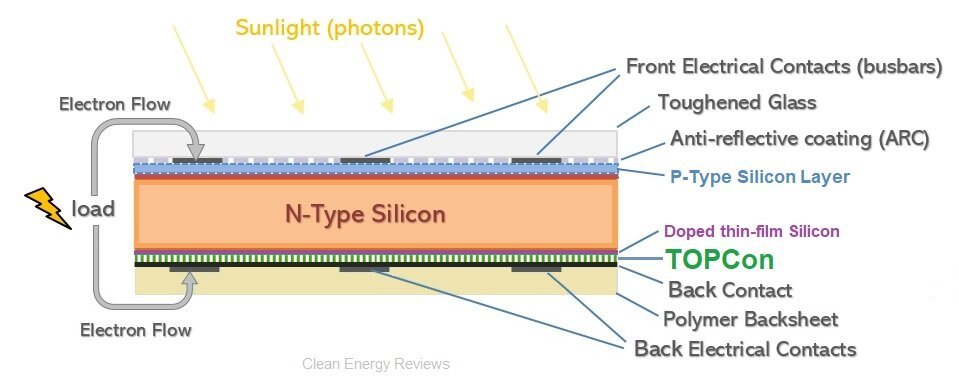

TOPCon solar cells

TOPCon stands for Tunnel Oxide Passivated Contact and is a more advanced N-type silicon cell architecture that helps reduce what is known as the recombination losses in the cell, which in turn increases cell efficiency. Due to a complex number of factors, several losses within a solar cell cause electrons to leak and recombine back into the silicon without forming an electric current. The ultra-thin TOPCon layer helps reduce this loss with a minimal cost increase to the production process. The TOPCon concept was first proposed by the German solar research institution Fraunhofer ISE back in 2014, but it wasn’t until 2019 that the technology was advanced enough to be deployed at scale and is now being used by several large manufacturers, including Trina Solar, JA Solar, Jinko and Longi Solar to achieve panel efficiencies above 23%.

Heterojunction - HJT cells

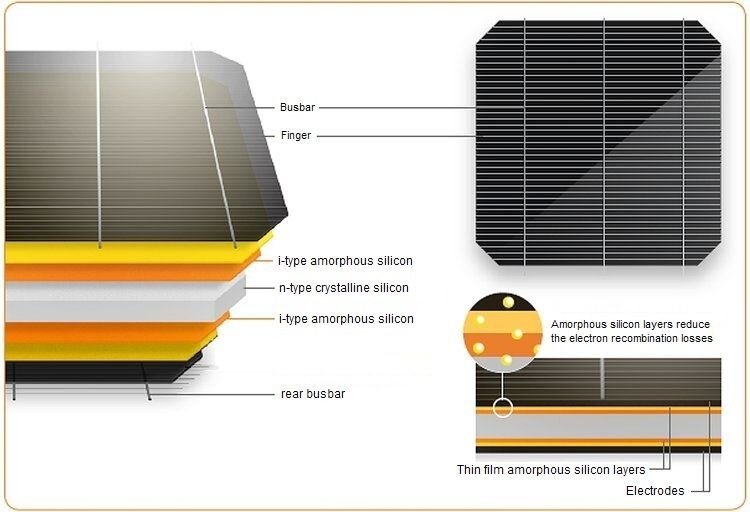

HJT solar cells use a base of common crystalline silicon with additional ultra thin-film layers of amorphous silicon on either side forming what is known as a heterojunction. The additional amorphous silicon layers reduce what is known as recombination at the N-P junction which essentially means it reduces loses and increases cell efficiency.

Panasonic created the efficient 'HIT' range of panels and was the leader in HJT cell technology for many years. REC group also recently released the Alpha series panels which use half-cut HJT cells combined with 16 micro busbars (16BB) to achieve an impressive 22.1% panel efficiency.

Panasonic HiT (HJT) cell construction - Image credit Panasonic Corporation

The unique Panasonic HIT panels are available in Japan and North America; unfortunately, they are not available in Australia. Considering the high average temperatures in Australia, they would be a great choice for rooftops and large-scale commercial applications.

Improved High-Temperature Performance

The most impressive characteristic of HJT cells is the incredibly low-temperature coefficient which is around 40% lower compared to common multi and mono silicon crystalline cells. Solar panel power is rated under Standard Test Conditions (STC) which is measured at a cell temperature of 25°C. Every degree above the STC temperature reduces power output by a small percentage known as the power temperature coefficient. In common multi and mono-cells, the temperature coefficient is 0.38% to 0.42% per °C which can add up to reduce total output by up to 20% during very hot windless days. In comparison, HJT cells have a very low 0.26%/°C temperature coefficient.

It is worth noting that panel and cell temperature are also affected by roof type, and colour, tilt angle and wind speed, so mounting panels flat on a very dark rooftop will usually reduce panel performance compared to lighter coloured rooftops.

Diagram highlighting the increased high temperature performance and efficiency of heterojunction cells.